Drill Bushing Cup (aka Drill Egg Cup).

The topic is Drill Bushing Cup, however, to get the discussion going on a humorous note… we have shown a photo of a traditional Egg Cup.

And, ask the question “Why the Cup on top of the Egg Cup? Duh … The correct answer, silly, is so the egg won’t fall off while you’re eating it 😉 .

Tradition Tools – Why Change?

Aircraft sheet metal technicians have been using “Drill Bushing Cups” or “Drill Egg Cup” for decades. They just always have. So if the aircraft industry is so concerned about function and design in all things aviation, why the cup on top of the Drill Bushing Cup?

I have often thought there is no practical purpose and therefore no obvious reason. Everyone has just used what is available, and what has been traditionally offered. We thought we would share the new ideas and design. We also wanted to produce the new tools at a reasonable price.

He is a New Design Idea

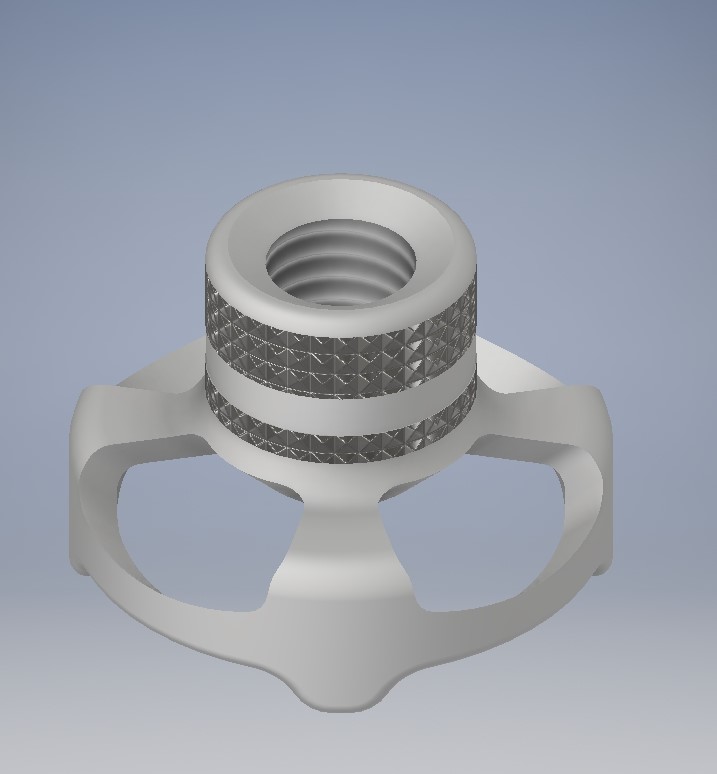

The image below shows what we call a “Drill Stand“. This new design, at least to us, still provides the prime reason for a drilling aid; that is, drilling the fastener hole at 90° to the surface of the skin or part.

We plan to offer the “Drill Stands” in two models.

- The first design will accommodate the 1/2″-13 TPI threaded drill bushings (shown above)

- the second model will accept the traditional 1/2″ OD Slip Fit Bushings and the SAS-Canada 1/2″ ID Doweled Bushings.

The inverted view in the above image shows the additional clearance provided for drill cuttings. The larger openings between the legs of the Drill Stand provide a less obstructed view and a better site line to the drill point, making it easier to start the fastener hole.

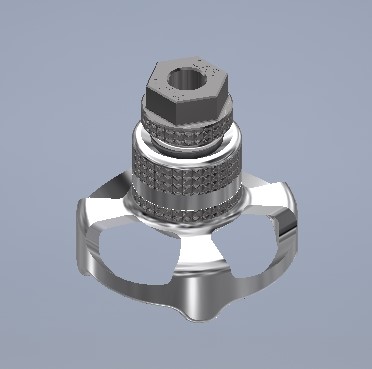

Improving the Drill Bushing

The drill bushings depicted above are also a new design. We have incorporated some subtle changes to the contact face between the Drill Stand and the Drill Bushing. The Drill Flute Cleaner machined into the bottom end of the drill bushing will be a significant design change is. Our first thought is to call this feature “Swarf Buster“. If anyone comes up with a more creative name or would like to offer a suggestion we would certainly give it consideration.

As the drill is retracted through the drill bushing, this feature will help remove the drill cuttings from the flutes of the drill. It will reduce the amount of clogging that typically occurs. Logically there will be less heat buildup and resulting wear to the drill bushing and drills, extending the service life of each.

We are in the process of manufacturing these new designs along with our traditional products, so be patient.

If you still want a Drill Bushing Cup, or as some call it a Drill Egg Cup, follow this link to our Online Store: https://www.sas-canada.com/store/drill-bushing-cup-egg-cup/

One response to “Why Does a Drill Bushing Egg Cup Need a Cup on Top?”

I’m still waiting on my order, I have not received any text messages or an email to let me know when my orders will be delivered, so I would appreciate if someone would let me know something.

Anthony Walker